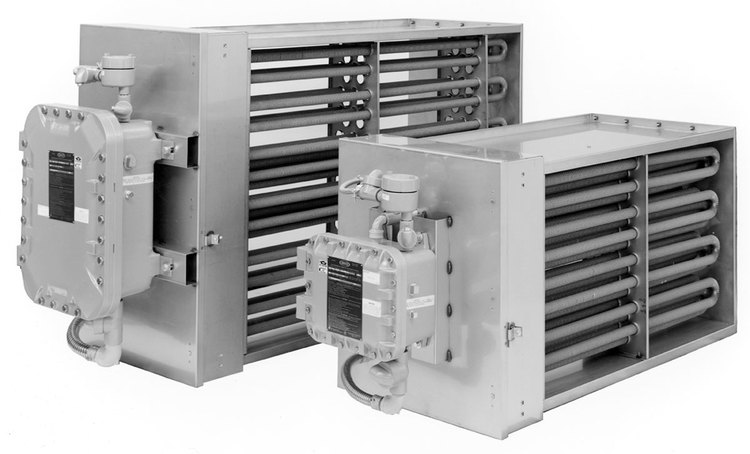

Series EP2 Explosion-proof Duct Heaters

Indeeco’s Class I, Division 2 Electric Duct Heaters are engineered for environments where hazardous gases are occasionally present—providing a powerful, reliable, and cost-effective heating solution. With cCSAus approval, these units are certified safe for use in classified areas, making them ideal for industrial ventilation systems that require both safety and performance.

Thanks to ongoing engineering innovations, Indeeco has made high-capacity electric duct heaters more accessible and versatile than ever. Designed to fit ducts up to 240" (610 cm) wide by 120" (305 cm) high, these heaters deliver up to 1000 kW of heat at voltages up to 600V, with ignition temperature ratings as low as 392°F (200°C).

Key Features:

- cCSAus Approved for Class I, Division 2 hazardous locations

- Ignition temperatures as low as 392°F (200°C) for increased safety

- Fits large duct sizes—up to 240" wide × 120" high

- High output ratings—up to 1000 kW and 600 volts

- Cost-effective alternative to custom-built hazardous area heaters

- Custom configurations available to meet specific airflow and control needs

Approvals

Standard Construction

Galvanized Sheet Metal Frame includes external flanges for field mounting and an element terminal box. Terminals are factory-connected to control safety components in an integral cast aluminum explosion-proof box.

Three Levels of Safety are provided on every heater: automatic and manual reset thermal cutouts, plus a fan interlock relay.

The automatic reset cutout, operating through the temperature control system, is the primary protector. The manual reset operates a separate backup magnetic contactor, independent of the temperature control system. The fan interlock relay prevents the heater from being energized, unless the fan starter is on.

Standard Built-in Control Package includes the following components mounted in a cast aluminum explosion-proof enclosure:

- De-energizing control and backup magnetic contactors.

- 24 volt control circuit transformer.

- Fan relay for heater/fan airflow interlock. Supplied with 120V or 24V coil to match the fan starter.

- Terminal blocks for field power and control wiring.

- Grounding terminal.

- Supplemental fusing for heaters drawing more than 48 amps.

Industrial Grade Heating Elements, built by Indeeco, are .475” (1.21 cm) diameter to provide extra insulation between the coil and sheath for high voltage protection. Stainless steel fins are helically wound onto the stainless steel sheath.

Control Options

Staged Control

Either single or multi-staged through a step controller, which may be built-in or remotely mounted. Each three-phase stage has a multiple of three elements to balance the electrical load.

Solid-State SCR Control

When temperature must be controlled precisely, built-in SCR’s are recommended. They are furnished with field-selected inputs of 2200 ohms, 135 ohms, 0-10 VDC, or 4-20 mA. SCR’s have zero-cross firing to eliminate radio frequency interference.

Custom Options

Built-in Step Controller

For two through ten heating stages. Input is field-selected at 2200 ohms, 135 ohm, 0-10 VDCs, or 4-20 mA.

Built-On Disconnect Switch

To meet NEC requirement for a disconnect at or within sight of the heater. (Not available for outdoor or washdown)

Built-on Airflow Switch

An explosion-proof differential pressure switch replaces the fan relay. Use only for positive pressure inside the duct. (Not available for outdoor or washdown).

Supplementary Fusing

For heaters drawing 48 amps or less. Fusing is standard above 48 amps.

“Warning” Pilot Light

Red light to indicate when a thermal cutout or airflow interlock has tripped.

“Heater On” Pilot Light

Green light indicates when there is power to the heater.

Disconnecting Magnetic Contactors

Contactors that break all ungrounded lines replace standard de-energizing contactors.

120 Volt Control Circuit

A 120V control transformer with both primary legs fused replaces the standard 24V transformer.

NEMA 4 Construction

Explosion-proof box is gasketed for outdoor or wet locations

Installation

Complete installation instructions are furnished with each heater. The following are some guidelines:

- The heater must be attached to external duct flanges.

- The heater must be adequately supported. If the duct flanges will not afford enough support, use overhead hangers for additional support.

- Airflow must be horizontal.

Classifications

- Class I, Division 2

- Groups C and D

- Temperature Code T3, 392°F (200°C)