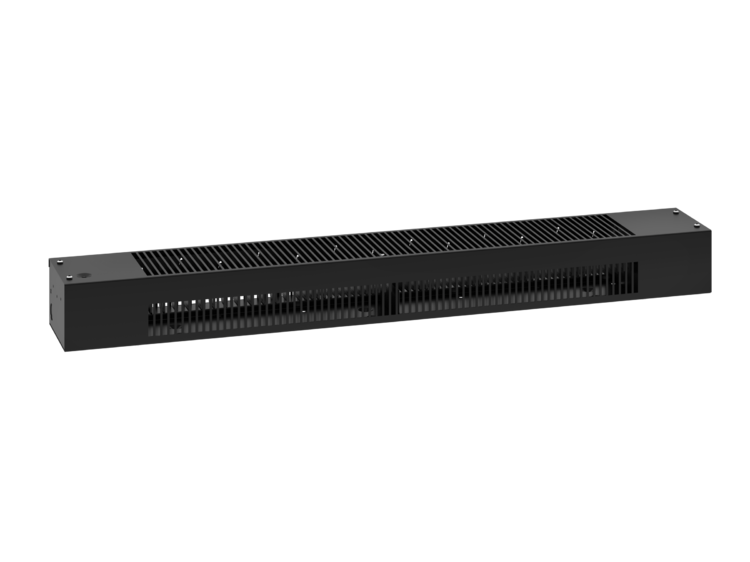

943 TRH Series Trench Insert Floor Convector

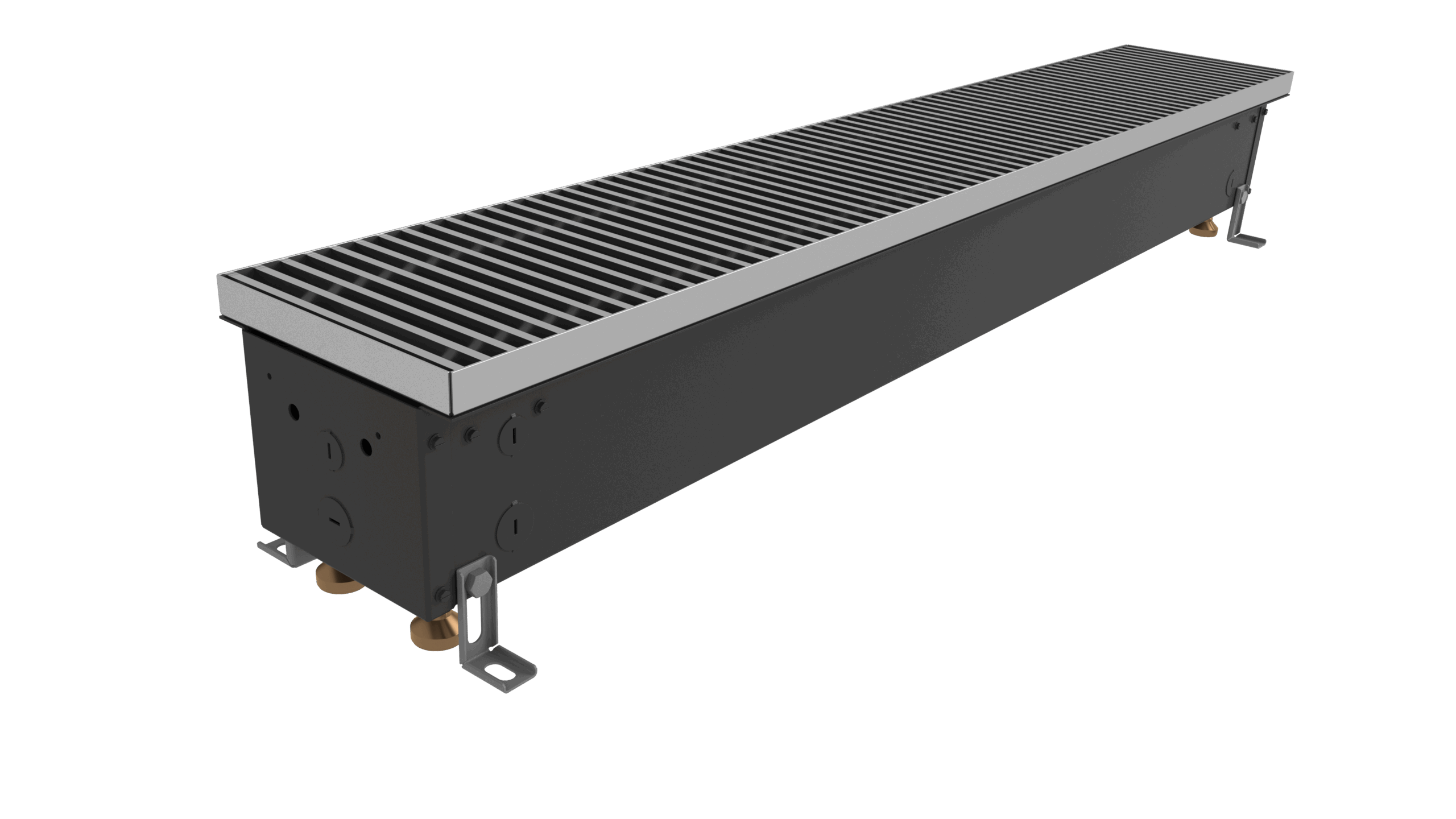

The TRH Trench Floor Insert Heater is an approved heating unit designed for installation beneath a floor-level grille within a site-built trench. Its versatile construction allows for a wide range of custom configurations, making it ideal for architecturally appealing applications where both performance and aesthetics are key.

- Heating element design accommodates a multitude of applications and heating needs

- Unique two-piece extruded aluminum closure design secures the one-piece top and front grilles to the one-piece back and bottom providing a rapid, secure fit along the length of the unit

- Front/bottom inlet air grille utilizes slots which create an attractive installation where inlet grille is visible

- Blend into any décor with custom finishes upon request

- Units can be mounted on floor, wall, or pedestals

- Customize space with wall-to-wall installation, or as discrete units in standard lengths of 28 in. to 12 ft.

- Units are available in a wide range of heating capacities per foot length (see specifications)

- Architectural-style end sections give a finished look when used as a stand-alone or where a wall-to-wall run is not desired

- Inside and outside corners can be ordered factory-cut and mitered to fit difficult or unusual spaces

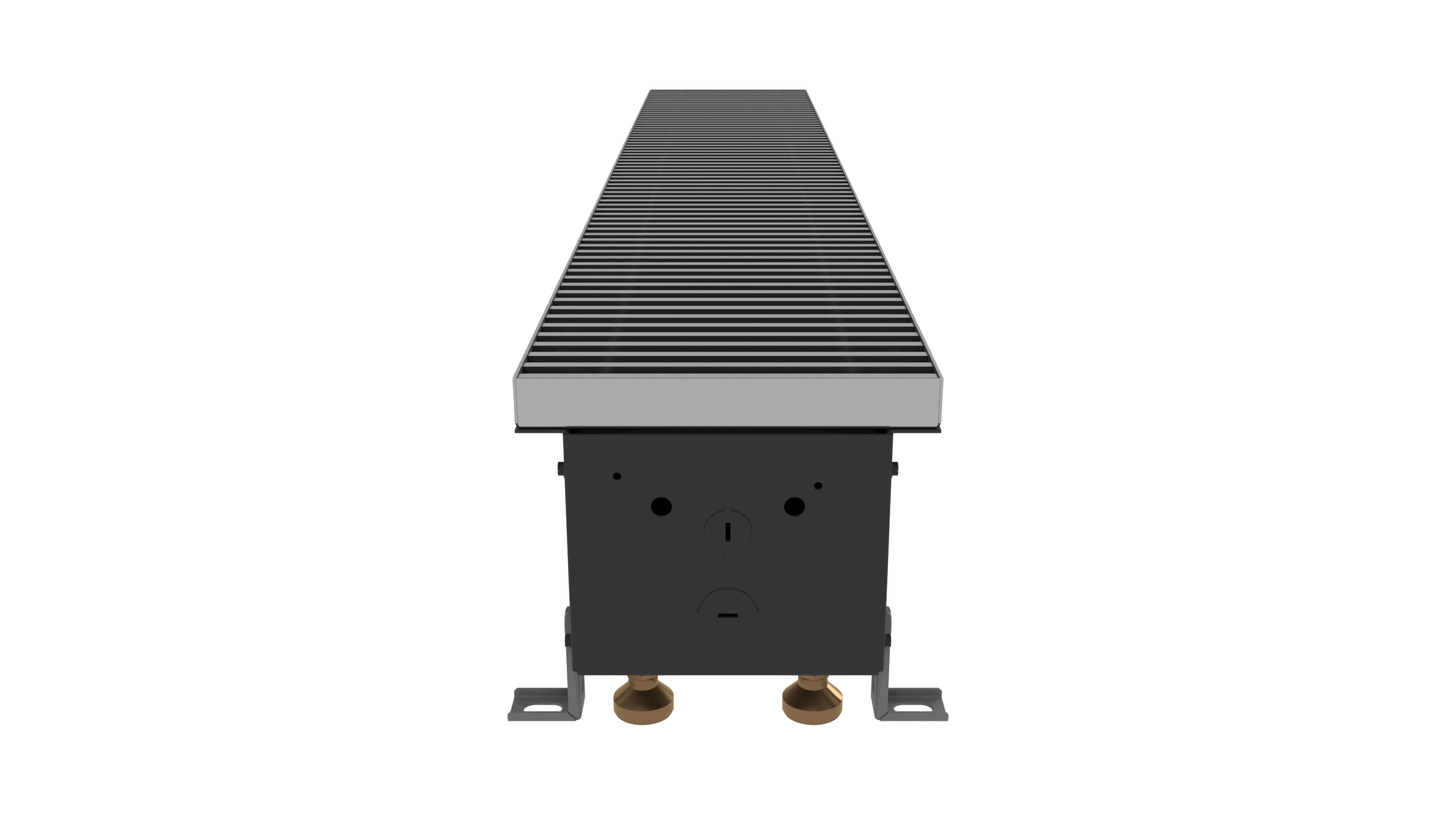

- Right -or left-hand entry and built-in wireway (equivalent to 3/4 in. conduit) with factory-installed wiring

- Full line of trim accessories, including matching blank sections, end caps, filler sections, inside and outside corners, diagonal end sections, and splice plates

- Optional built-in controls include: line-voltage thermostat; two-stage thermostat; on/off switch; transformer relay; power relay.

- Easy connection of supply wiring from bottom, rear or end, as well as multiple wiring of adjacent heaters from one entry point

- Thermal limit switch with linear type (full length) sensing bulb provides constant protection against overheating. Switch will automatically reset when normal operating temperatures are restored

- Discharge air openings in top grille are punched slots which are pencil-proof for safety

Approvals

Standard Features

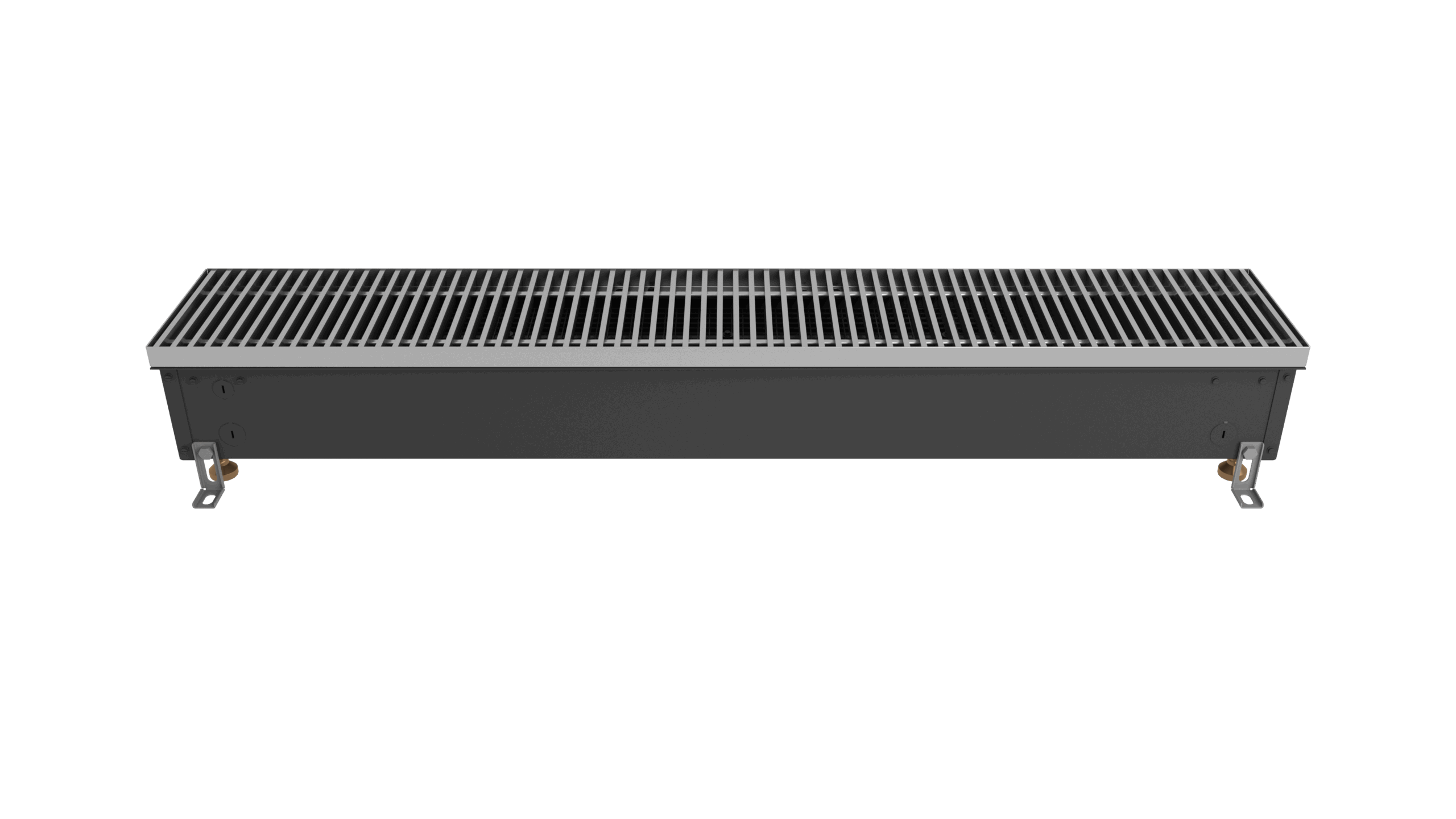

CABINET / GRILLES: Shall be 16-gauge (.060″ min.)

galvanneal steel enclosure, with a heavy-duty gauge,

extruded, architectural aluminum bar grilles. The unit shall

have the capacity to hold over two times the allowed UL

listing weight. Each grille bar shall be of concave design. The

grilles shall be either flush mount or surface mount, and

come in multiple color / finish options.

SIZE: Heaters shall be of zero vertical profile, with the entire

enclosure recessed in the floor (61/8″ x 77/8″) and available

in standard lengths from 2–5 feet, with modular lengths

above 5 feet.

HEATING LENGTHS, VOLTAGES, WATTAGE: Heater lengths,

voltages and wattage capacities shall be as indicated on

the plans.

FINISH: The grille shall be finished with polyester powder

paint or anodized phosphate coating to resist corrosion.

WATER AND DEBRIS MANAGEMENT: Heater shall include

gaskets / seals for all control compartments in order to deter

the entrants of water and debris. Each unit shall include a

debris catch screen just below the grille, that will impede

debris from falling inside of the unit and onto the elements.

HEATING ELEMENTS: The nickel-chromium heating element

wire shall be encased in a magnesium phosphate material

inside a steel sheath for maximum, trouble-free element life.

Aluminum fins shall be pressure bonded to the steel sheath.

Elements shall be centered anchored and shall float freely at

each end through high-temperature Noryl bushings. Stainless

steel elements with aluminum fins shall also be available.

WIRING, ELECTRICAL, SAFETY: Units shall be UL listed

with gasketed junction boxes, end-to-end wire way, and

multiple knockout locations for field wiring entry on either

end or bottom. Heaters shall contain a dual safety limit chain

standard, with both manual and automatic reset. All optional

factory, build-in controls will be included in every unit, with no

separate control sections needed unless otherwise indicated

on the plans.

MOUNTING: Heaters are listed for three mounting options,

out of the box: frame mounted, concrete pour, direct on

slab with legs. The heater shall come standard with 4

adjustable leveling legs, and configurable with mounting

legs for additional securing points.

OPTIONAL BUILT-IN CONTROLS: Power on / off switch,

power relay, low-voltage control relays, and, singly or in

combination, may be specified for factory installation in

heaters. All optional factory build-in controls, and manual

reset, are accessible via removal of the junction box covers.

Applications

Conference Rooms

Hallways

Lobbies

Offices

Retail Spaces

Floor-to-Ceiling Curtain Walls