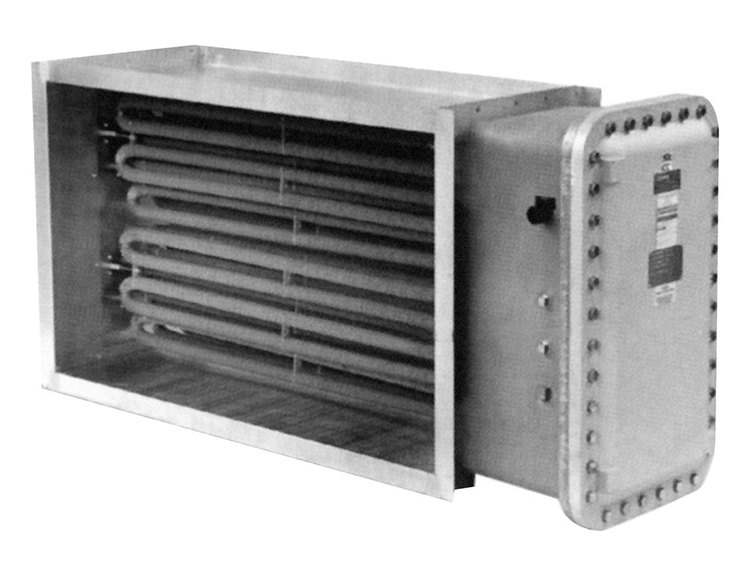

Custom Explosion-proof Duct Heaters

The Custom Explosion-proof Duct Heaters and EP2-V Series Unit Heater offer a wider range of sizes than other models, with power ratings up to 750 kW and voltages up to 600V, making them ideal for demanding industrial environments where safety and performance are critical.

Designed for vertical airflow, the EP2-V Series delivers efficient overhead heat distribution, ideal for facilities with ceiling-mounted or elevated heating requirements. Units are constructed to the rugged standards of the EP2 Series, with an enhanced design: element terminals and control components are housed together in a single cast aluminum explosion-proof enclosure, providing reliable protection in hazardous or classified areas.

Construction

Frame

Sized to fit the duct. Standard flanged design recommended to support heater weight. Slip-in also available, if necessary, to match other equipment. Galvanized steel standard; stainless steel optional.

Control Enclosure

NEMA 7, 9 cast aluminum box with hinged cover houses controls and element terminals. Weatherproof construction optional.

Heating Elements

Heavy wall, large diameter stainless steel finned tubular elements, individually removable for servicing.

SCR Temperature Control

SCR’s with zero-cross firing provide precise proportional control. SCR’s also minimize element operating temperatures for extra safety. Optional on/off single or multi-stage control also available.

Control Transformer

Furnished as standard with fusing as required.

Overtemperature Protection

Thermocouple controllers measure element sheath temperature.

- Automatic reset control resets when temperature drops to a safe level.

- Manual reset control, with external button, provides back-up protection.

Fuses

Individual circuit fusing for heaters drawing over 48 amps to meet NEC requirements.

Airflow Interlock

Fan relay prevents heater operation, unless fan is energized. Optional builtin or remote explosion-proof airflow switch can be provided.

Magnetic Contactors

Furnished as required for temperature and safety controls.

Classifications

- Class I, Division 1 and 2 Groups C and D

- Class II, Divisions 1 and 2 Groups E, F, and G