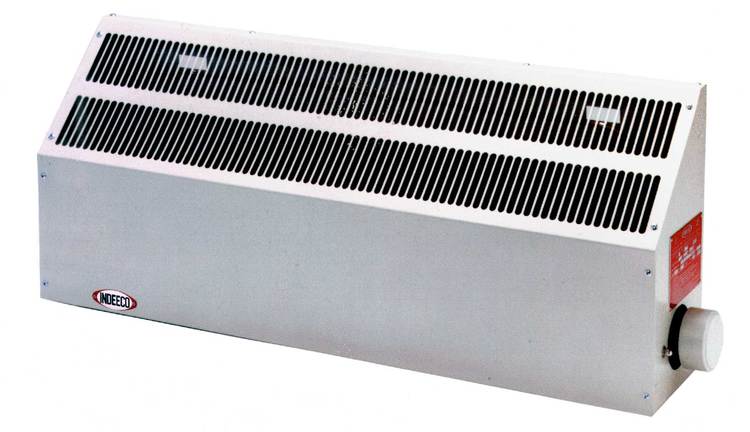

Explosion-proof Convector

Indeeco’s Explosion-Proof Convector Heater is specifically engineered to deliver dependable heating in areas where explosive gases, vapors, or dust may be present. Designed for both safety and durability, this unit provides a heavy-duty, corrosion-resistant heat source ideal for harsh industrial applications.

Constructed with high-quality materials and built to meet stringent safety standards, this heater is certified for use in Class I, Division 1 and Division 2 hazardous locations, as well as Class II, Groups E, F, and G. Its low-profile, wall-mounted design ensures space-saving installation without sacrificing performance. It provides silent, convection-based heat without moving parts, reducing maintenance and improving reliability in remote or hard-to-access locations.

Whether it’s a chemical processing plant, offshore oil platform, or fuel storage terminal, the Indeeco Explosion-Proof Convector ensures consistent and safe operation, even in the most demanding environments.

Approvals

Standard Features

Wide Selection of Sizes

Four compact sizes to fit any space with ratings from 500 to 9,500 watts.

Sloped Top Cabinet

Prevents objects from being set on top of the convector, which can restrict airflow and cause overheating.

Single and Three-Phase

Unique design provides single and balanced three-phase loads in a single element.

Gas and Dust Atmospheres

Three listings cover the entire field, two for hazardous gases and vapors and one for dust particles.

Wet Locations

All unit sizes available with iriditecoated elements and powder-coated frames for NEMA 3 wet locations.

Element

Grade A Nickel-Chromium heating coils are insulated with ceramics and magnesium oxide from the copper heater tube and fitted with large aluminum fins locked in place.

Cabinet

Heavy gauge galvanized steel cabinet is painted with a beige powder coat for durability. Cabinet should be mounted at least 6 inches (152 mm) above the floor. Factoryfurnished wall brackets make installation easy.

Thermal Protection

A linear limit, automatic reset thermal cutout is built into every unit.

Complete Electrical Package

For larger single-phase and all three-phase units, a built-on contactor and transformer option package are available.

Electrical Package Options

All single-phase heaters rated over 22 amps or 277 volts and all three-phase heaters require a magnetic contactor. Some electrical combinations will also require a control transformer. To simplify field installation, these accessories are factory-mounted on the heater cabinet and factory prewired (not available on Size 1 convectors).

Electric Control Option (without thermostat)

Classes I and II, Groups B, C, E, D, F and G includes contactor and transformer (as required). Required for all three-phase and single-phase heaters over 22 amps or 277 volts

Thermostat & Controls

Classes I and II, Groups C, D, E, F and G includes thermostat, contactor and transformer (as required).

Thermostat & Controls (Group B)

Classes I and II, Groups B, C, D, E, F and G includes thermostat, contactor and transformer (as required). Thermostat has internal set point.

Thermostat Only

Classes I and II, Groups C, D, E, F and G single-phase heaters rated up to 22 amps at 120-277 volts. Use remote room thermostat Catalog Number 1007002 for Size 1 convectors.

Thermostat Only (Group B)

Classes I and II, Groups B, C, D, E, F and G single-phase heaters rated up to 22 amps at 120-277 volts. Thermostat has internal set point. Use remote room thermostat Catalog Number 1007002 for Size 1 convectors.

Custom Options

Wet Locations

Type 3 rated construction. Includes Iridite coated element assembly and gasketed terminal box. Not available with options B2/S1, S1, or S2.

Corrosive-Resistant Stainless Steel Construction

Type 3 rated construction with addition of stainless steel cabinet. Includes Iridite coated element assembly and gasketed terminal box. Not available with options B2/S1, S1, or S2. ONLY the cabinet is upgraded to stainless steel.

Accessories

Remote Thermostat

A remote wall mounted thermostat is available.

Classifications

- Class I, Divisions 1 and 2, Groups B, C and D

- Class II, Divisions 1 and 2, Groups E, F and G

- Class I, Zones 1 and 2, Groups IIB and H2

Applications

Battery Storage Areas

Chemical Plants

Coal Handling Facilities

Dry Cleaning Plants

Gasoline Fueling/Storage Areas

Grain Elevators

Oil Refineries

Paint Spraying/Storage Areas

Petrochemical Plants