Cooling Tower Panels

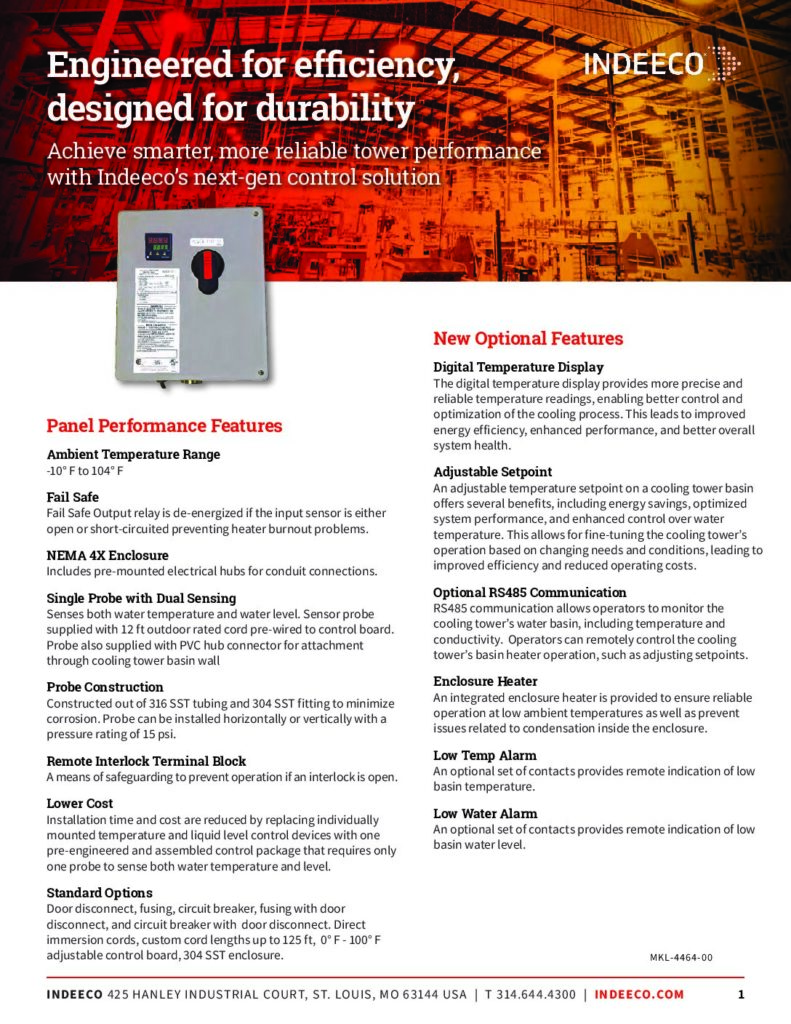

Indeeco Cooling Tower Control Panels provide a streamlined, cost-effective solution by replacing multiple individually mounted temperature and liquid level control devices with a single, pre-engineered and factory-assembled control package. Designed to simplify installation and reduce labor costs, these panels are ideal for managing cooling tower operation efficiently and reliably.

Built with quality components and engineered for dependable performance, Indeeco control panels help maintain optimal system performance while minimizing complexity in the field.

Approvals

Panel Performace Features

Ambient Temperature Range

-10° F to 104° F

Fail Safe

Fail Safe Output relay is de-energized if the input sensor is either open or short-circuited preventing heater burnout problems.

NEMA 4X Enclosure

Includes pre-mounted electrical hubs for conduit connections.

Single Probe with Dual Sensing

Senses both water temperature and water level. Sensor probe supplied with 12 ft outdoor rated cord pre-wired to control board. Probe also supplied with PVC hub connector for attachment through cooling tower basin wall

Probe Construction

Constructed out of 316 SST tubing and 304 SST fitting to minimize corrosion. Probe can be installed horizontally or vertically with a pressure rating of 15 psi.

Remote Interlock Terminal Block

A means of safeguarding to prevent operation if an interlock is open.

Lower Cost

Installation time and cost are reduced by replacing individually mounted temperature and liquid level control devices with one pre-engineered and assembled control package that requires only one probe to sense both water temperature and level.

Standard Options

Door disconnect, fusing, circuit breaker, fusing with door disconnect, and circuit breaker with door disconnect. Direct immersion cords, custom cord lengths up to 125 ft, 0° F – 100° F adjustable control board, 304 SST enclosure.

New Optional Features

Digital Temperature Display

The digital temperature display provides more precise and reliable temperature readings, enabling better control and optimization of the cooling process. This leads to improved energy efficiency, enhanced performance, and better overall system health.

Adjustable Setpoint

An adjustable temperature setpoint on a cooling tower basin offers several benefits, including energy savings, optimized system performance, and enhanced control over water temperature. This allows for fine-tuning the cooling tower’s operation based on changing needs and conditions, leading to improved efficiency and reduced operating costs.

Optional RS485 Communication

RS485 communication allows operators to monitor the cooling tower’s water basin, including temperature and conductivity. Operators can remotely control the cooling tower’s basin heater operation, such as adjusting setpoints.

Enclosure Heater

An integrated enclosure heater is provided to ensure reliable operation at low ambient temperatures as well as prevent issues related to condensation inside the enclosure.

Low Temp Alarm

An optional set of contacts provides remote indication of low basin temperature.

Low Water Alarm

An optional set of contacts provides remote indication of low basin water level.