A natural gas fueled turbine for electric power generation requires the natural gas to be free of liquids. The gas must be superheated a minimum of 50ºF to ensure that it is 100% free of liquids. This process is often called last chance filtering. Electric circulation heaters can be used to provide the necessary heat to this process.

Design Requirements

This job required two (2) circulation heaters and control panels which were sold to a skid integrator who packaged the system. Each circulation heater was rated 495 KW at 480 volts, 3-phase and capable of superheating 48,000 lbs/hr of natural gas 50ºF with a minimum inlet temperature of 40ºF and a maximum outlet of 110ºF. Each circulation heater is required to be ASME stamped with a design temperature of 375ºF at 550 psig. Both the circulation heaters and control panels are to be suitable for outdoor use and designed for Class I, Division 2, Group D hazardous locations. No agency approvals are required.

Solution

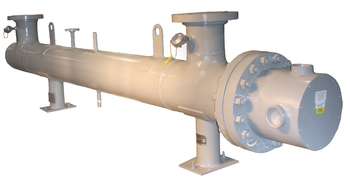

Circulation heater(s) – Model 350-series horizontal circulation heater with ASME section VIII, Div 1, U stamp vessel and heater, 12-inch steel vessel with 12-inch 300 pound flanges. Elements were .475 diameter Incoloy 800 sheathed with 23 watts per square inch density. Over temperature and process control thermocouples were provided for temperature sensing.

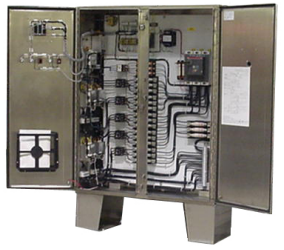

Remote control panel(s) – Model 870 series NEMA 4 panel with Type Z-Purge system, door interlocked disconnect switch, magnetic contactors, power fuses per circuit, PID temperature controller with digital display and Indeeco Controls ten (10) stage microprocessor based sequencer. Full function operational and alarm indication for local and remote DCS control were included.

Indeeco Advantages

What won the order for Indeeco? The heat transfer system manufacturer had previously worked with a well known competitor who underperformed and failed to supply the correct equipment. The customer was left in a bind and turned to Indeeco for help. After the customer toured the Boonville plant and met with our engineers they were confident that Indeeco could do the job for them. They have promised an order for a second job and we have quoted several other jobs to them. Although Indeeco stopped manufacturing heat transfer systems several years ago we are more than capable of supplying a wide range of quality built ASME approved circulation, process air heaters and control panels to skid manufacturers.