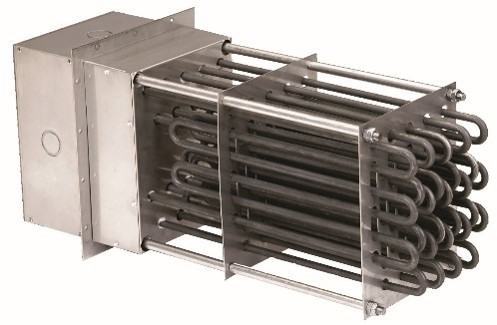

Tubular Process Air Heaters

Built with robust construction, Indeeco’s Tubular Process Air Heater is ideal for demanding environments where moisture and particulates are present in the airstream. Its durable design ensures long-lasting performance and reliability across a wide range of industrial process heating applications.

Standard Features

Heavy steel or stainless steel flange with pre-drilled mounting holes.

Multiple concentric knockouts on all sides of the terminal box for convenient conduit entry.

Louvered terminal box cover keeps connections and wiring at safe temperatures.

Pressure connectors welded or bolted to bus bars furnished for field wiring of 8 gauge and heavier.

Removable bus bars are secured with stainless steel nuts and shakeproof washers.

Individually replaceable elements mounted to the terminal flange with push nuts.

Stainless steel terminal hardware and 10-32 threaded studs assure reliable connections.

304 stainless steel support brackets with contoured openings to allow the elements to expand and contract smoothly.

1/2″ diameter steel rods tie the assembly together in a rigid, yet expandable, mode.

Recompressed bends eliminate hairline cracks in insulation, extending element life.

Elements are .475″ diameter Incoloy 840 sheath.

Unique bending configuration reduces the number of element terminals by more than half, lowering terminal box temperatures. Terminal box may be side or top mounted.

1″ of insulation in terminal box standard for outlet temperatures up to 750° F. 4″ insulation below mounting flange standard for 1200° F construction. Optional for other constructions.

Open framework allows universal mounting. Use with horizontal or vertical airflow.

Special Features

Built-in Controls

(Available for heaters operating up to 150° F outlet air temperature.)

Built-in contactors, fuses, control transformers, and disconnect switches save installation labor and provide single source responsibility for the heater-control package.

Built-in Thermostat

(Available for heaters operating up to 150° F outlet air temperature.)

For automatic control of outlet air temperature. Adjustable over a range of 60-250° F. Outlet temperature will be lower than set point as the thermostat senses heat from elements as well as outlet air. Do not use where outlet air temperature will exceed 150° F. May also be used as an automatic high temperature thermal cutout.

Built-in Combination Thermostat/Thermal Cutout

(Available for heaters operating up to 150° F outlet air temperature.)

Control normally cycles the heater on and off, but shuts the heater down until reset button is pressed if temperature rise is more than 50° F above the control set point. (60-250° F range).

Remote Mounted Thermostats

For air temperature control or high temperature thermal cutout protection, a bulb and capillary type thermostat can be mounted in a cool location up to 8′ away from the heater. A well is provided to mount the thermostat bulb into the airstream.

Built-in Thermocouple

Built-in sheathed thermocouple available for high temperature limit. This can be mounted in the airstream or clamped to a tubular/finned tubular element to prevent overheating.

Built-in Airflow Switch

(Available for heaters operating up to 150° F outlet air temperature.)

A diaphragm-operated differential pressure switch normally prevents the heater from operating unless the air is flowing. It senses pressure between process air and the terminal housing.

Moisture-Resistant Element Seal

RTV or epoxy seals are inserted into each end of tubular or finned tubular elements. Recommended when heater may be stored in high humidity or where terminals are exposed to high humidity during operation.

Flanged Duct Mounting

For attaching heater to external duct flanges. No internal support required. Note that heater face dimensions W and H match the inside dimensions of the duct. While integral flange design is standard on the 250° F Construction, other heaters can be supplied with separate flange mounted plenum sections where required.

Flanged Terminal Box

A 1″ full flange at end of terminal box is available for mounting heater. Especially useful when heater is mounted inside

Angle Iron Frame

(Available for all tubular and finned tubular heaters except those with 250° F Construction.)

Support rods are replaced by heavy angle iron welded to element supports and terminal box. May increase C and H

Isolated Junction Box

Power connections are housed in a separate isolated junction box, factory connected to heating element terminals. Used where field wiring is not suitable for high ambient temperatures.

Airtight Terminal Box

(Available for all tubular and finned tubular heaters except those with 250° F Construction.)

Terminal box isolated from the duct or oven with compression fittings on each element to prevent leakage of process air into terminal box.

Dust-Tight Terminal Box

For dirty environments. Boxes are welded, stainless steel with hinged, latched cover and Scru-tite hubs for incoming power. Insulation under the mounting flange is required for all heaters operating above 250° F outlet air.

Special Materials

Nonstandard fin, sheath and frame materials available for special applications. Finned tubular elements available with Monel sheath and fins. Tubular elements available in Monel, 304 and 316 stainless steel and Inconel sheath. Stainless steel frames available for all constructions.

Nonstandard Circuiting

Additional circuits available on standard heaters. However, number of circuits must be consistent with number of elements in tubular and finned tubular constructions. Number of circuits shown in standard listings can also be reduced for high amperage SCR control.

Insulation Under Mounting Flange

Insulation is furnished under mounting flange to save energy and reduce terminal housing temperatures. This is standard on 1200° F Construction and optional on all others.

Special Wattage, Voltage and Dimensions

Indeeco specializes in custom designed process air heaters.

Voltages up to 600V are available in single or three phase. dimensions. Specify steel or stainless steel angle iron. an oven, where ready access to electrical connections and minimum terminal box size are desirable. No terminal box cover is supplied.

Applications

Indeeco Process Air Heaters are installed in plenums, ducts or pipes to heat forced air in industrial equipment and systems. A wide variety of heater designs and sizes are available to provide outlet air temperatures up to 1200° F. The air can be either recirculated or fresh. Recirculated air is used to reduce power consumption and heater size. Fresh air is used when ventilation of the process is necessary.

Process air heaters are installed in ovens, furnaces, autoclaves, dryers, conveyor systems, pressure vessels, and other equipment to supply the precise amount of clean heat for:

Aircraft Manufacturing

Air Curtains

Air Drying

Annealing

Booster Heating

Baking

Batch Heating

Chemical Processing

Cooking

Core Drying

Cryogenic Exhaust Gas Heating

Curing

Dehumidification

Dehydrating

Drying

Exhaust Gas Heating

Film Drying

Finishing Systems

Food Processing

Fruit Ripening

Heat Recovery Supplement

Heat Treating

Hopper Heating

Ink Drying

Laboratory Testing

Make-up Air Heating

Metal Finishing

Motor Winding Burnoff

Paint Baking/Drying

Pharmaceutical Manufacturing

Plastic Curing

Preheating

Reheating

Roasting (nut, coffee, corn, etc.)

Semi-Conductor Manufacturing

Sterilizing

Standby Heating

Textile Drying

Varnish Drying

Wire Manufacturing