In 2015, Burns and McDonnell contracted with Indeeco to build two process heating systems to be installed in large energy plants located in the US. The heating systems were installed at the supply stream of service water to the Reverse Osmosis equipment, which would enable continuous full capacity of demineralized water production during colder ambient conditions.

Indeeco designs and manufactures custom and standard electric heating solutions for industrial skid-mounted process heating applications, at virtually any order volume.

Ask More.

In 2015, Burns and McDonnell contracted with Indeeco to build two process heating systems to be installed in large energy plants in the US. Previously the large plants were experiencing reduced capacity during colder ambient conditions.

Expect More.

Indeeco sales and engineering staff worked closely with Burns and McDonnell to develop the right solution while avoiding unnecessary cost.

Do More.

The heating systems were installed at the supply stream of service water to the Reverse Osmosis equipment, which enabled continuous full capacity of demineralized water production at lower temperatures. Indeeco’s flexible manufacturing capabilities enabled Burns and McDonnell to complete the project ahead of schedule.

Discover More.

During the course of power generation, the plants closed loop steam line lost demineralized condensate from normal steam drum blowdown or other vents and drains.

To produce demineralized water, the water source had to first be processed through a reverse osmosis system. The lower ambient conditions created two issues; first the lower water temperature made the filtering less efficient since a higher temperature allowed greater flow. Second, reverse osmosis membrane elements and systems are rated at 77°F (25°C).

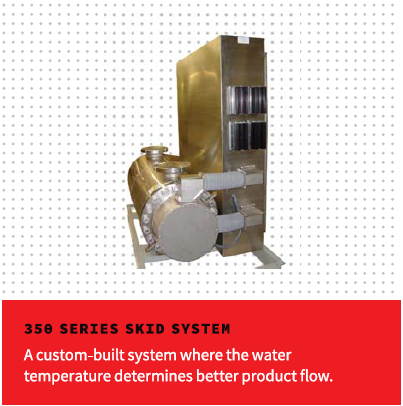

With the water source being piped into the facility, a circulation heater was the clear choice for the project. In addition to the circulation heater, Burns and McDonnell requested a control panel to support the heater. They followed the panel request with a desire to have the heater and panel packaged and prewired as a complete unit.

Indeeco provided Burns and McDonnell with two ASME certified 360 Series Skid Systems rated at 660 kW each capable of heating water to 77°F (25°C) with a flow rate of 150 gpm.