Open Coil vs. Finned Tubular Elements | Making the Selection

If you are trying to decide which type of heating element would best suit your needs, and are looking to compare Open Coil vs. Finned Tubular elements, look no further! Find out the difference between the two types of heater construction and some tips on how to select the right heater for your application.

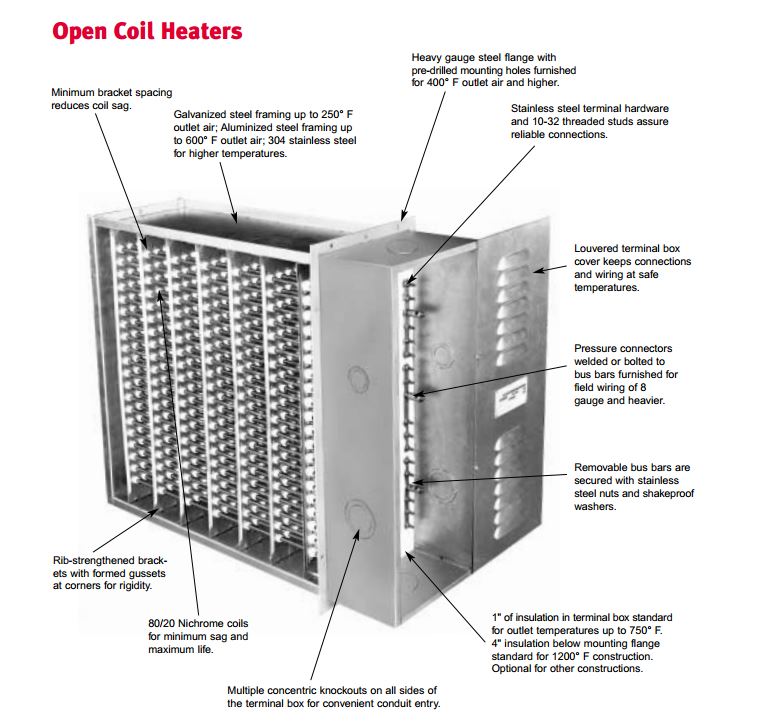

Open Coil

The following image shows the construction of an Open Coil heater.

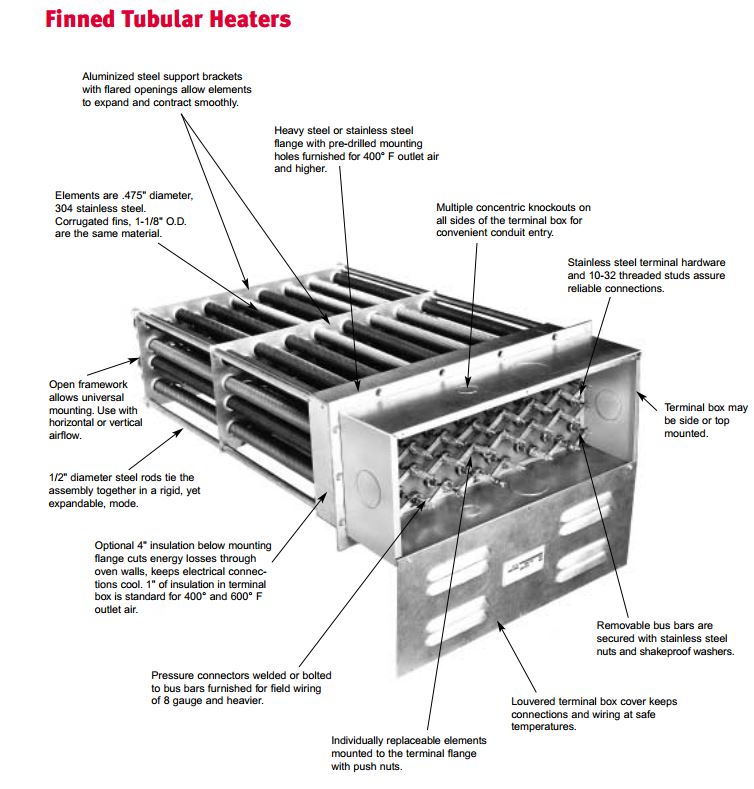

Finned Tubular

The following image shows the construction of a Finned Tubular heater.

Selection Tips

Now that you have seen the difference in construction between the two, here are a few tips to help you make the best decision for you.

1. COST

When looking at the cost of the heater, consider that generally Open Coil heaters have a more economical construction. This is because open coil offers low pressure drop and heater weight as well as quick thermal response. Finned Tubular construction tends to be more expensive since it is able to accommodate higher watt densities.

2. OPERATING TEMPERATURE

Finned Tubular designs are recommended at 600 degrees Fahrenheit for maximum outlet temperature. In comparison, Open Coil designs are recommended up to 1200 degrees Fahrenheit for maximum outlet temperature.

3. AIR VELOCITY

Both designs are capable of withstanding high air velocities, but only Finned Tubular and Tubular designs can handle 2500 feet per minute and a Finned Tubular design can handle air velocities of up to 5000 feet per minute.

4. AIR QUALITY

For applications where no water spray or conductive particles contaminate the air, Open Coil construction is best, while Finned Tubular can be used with most air contaminates unless there is a possibility build up from the contaminates can collect between the fins.

Consider the first 4 tips the most important when considering the right heating element choice for your application, if there is no clear winner after considering these 4 variables, the following 6 should help you to determine the best choice.

5. PRESSURE DROP

Pressure drop depends on the space occupied in the heater by the elements, the less space occupied the lower the pressure drop. This means that heaters with open coil elements have the lowest pressure drop.

6. COIL TEMPERATURE

Finned Tubular elements runs hotter than open coil. Unlike coils that are embedded in sheathed elements, open coil elements run cooler when exposed directly to the air stream.

7. SAFETY

In Finned Tubular elements the risk of shock hazard from accidental contact is eliminated. If there is a chance that people or conductive material can come in contact with a heater element, safety is a concern and Open Coil heaters are not recommended since there is no metal sheath and the coils are electrically live.

8. CONTROLLABILITY

Open coil heaters have a low thermal inertia which results in a quick response to step control. Unless the controls compensate, this can cause temperature fluctuations. With a high thermal inertia finned tubular elements have a slower response but produce more uniform temperatures (if the control system is properly designed).

9. ELECTRICAL CLEARANCES

With small clearances between their resistance wire and the sheath, finned tubular elements are filled with compacted magnesium oxide this magnesium oxide acts as an insulator. Better suited to withstand severe applications, Open Coil heaters have a large clearance between the live parts of the heating element and ground.

10. AIRFLOW UNIFORMITY

To operate properly, Open Coil heaters have uniform airflow and do not tolerate hot spots. Finned Tubular designs are more tolerable non uniform airflow because the sheath and fin design tends to dissipate hot spots.

Hopefully this article has been an aide to you in researching the best heater for your application. Whether you are looking for Open Coil or Finned Tubular elements, it is important to choose the best type of construction for your unique application. For more information please contact us at www.indeeco.com.