TRIAD® Washdown/Corrosion Resistant Unit Heater

Indeeco can provide a perfect solution to those who have a problem of heating people or equipment in non-hazardous environments, where moisture and corrosion may exist. The TRIAD® washdown/corrosion resistant unit heater is that perfect solution! Read about the advantages, standard construction features and types of applications that have worked well this type of heater.

Advantages

Below is a list of advantages of the TRIAD®:

- Built-in Controls: All the necessary safety and temperature controls are included in a single package. Components and motors are factory-wired into a single terminal block for field wiring, eliminating the chance for field error and reducing installation costs.

- Single Point Electrical Hook-up: Heater, fan motor and controls are all connected to the same branch circuit.

- Corrosion Resistant: Stainless steel construction, powder-coated aluminum fan blade and nonmetallic NEMA 4X terminal enclosure resist corrosion found in sewage treatment plants, swimming pool areas, car washes, paper mills and marine installations.

- Washable: This watertight construction can be hosed down without disconnecting the heater, which makes it ideal for coal handling areas, steel mills, foundries, ships, wood finishing plants, cement, sand, grain and food processing facilities.

Standard Construction Features

All the TRIAD® washdown/corrosion resistant unit heaters have standard construction features:

- Heating Elements: Industrial grade, Type 316 stainless steel tubular elements with stainless steel fins, manufactured by INDEECO.

- Fan Motor Assembly: Totally enclosed, epoxy coated, UL Recognized motor with permanently lubricated ball bearings for longer life. Designed to resist moisture and corrosion. Factory-wired to NEMA 4X enclosure. Fitted with a powder-coated, aluminum fan blade suitable for corrosive salt spray environments.

- Housing: Heating elements and motor are enclosed in a round, heavy 16-gauge stainless steel shroud.

- Inlet/Outlet Grilles: Adjustable, stainless steel, louvered outlet grille can be rotated 90° direct airflow up, down, left or right. Heavy gauge, stainless steel rear grille protects against accidental contact with the fan blade.

- Control Enclosure: The non-metallic enclosure, which houses the element terminals and built-in controls, will not rust and meets NEMA 4X hose-down requirements.

- Built-in Controls: Include automatic reset overtemperature cutout, fan delay relay, controlling contactor, transformer for 24-volt control circuit, terminal block for field wiring and a separate motor contactor (when required).

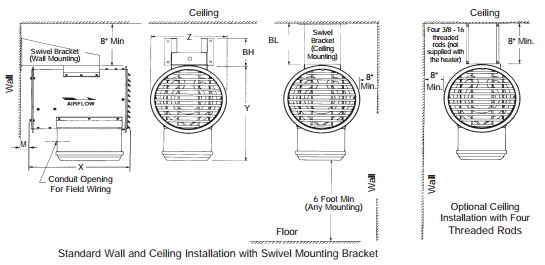

- Mounting Bracket: The heater will come complete with a stainless steel swivel mounting bracket which can be used either for wall or ceiling mounting. Four field-supplied ⅜-16 threaded rods can also be used for ceiling installation.

Applications

There are a few applications that the TRIAD® washdown/corrosion resistant unit heaters have worked well with:

- Car washes

- Cement plants

- Coal handling areas

- Dairies

- Food processing plants

- Marine and offshore

- Power generating stations

- Steel mills and foundries

- Swimming pool areas

- Wastewater treatment plants

Please contact Indeeco to discuss how the TRIAD® washdown/corrosion resistant unit heaters will fit your heating need, www.indeeco.com.