The Importance of Normalizing

Normalizing is a thermal process often associated with forgings. Why do we normalize? The following article answers just that question.

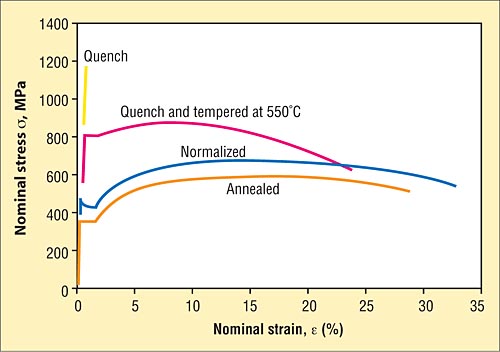

Normalizing imparts both hardness and strength to iron and steel components. In addition, normalizing helps reduce internal stresses induced by such operations as forging, casting, machining, forming or welding. It also improves microstructural homogeneity and response to heat treatment (e.g. annealing or hardening) and enhances stability by imparting a “thermal memory” for subsequent lower-temperature processes. Parts that require maximum toughness and those subjected to impact are often normalized. When large cross sections are normalized, they are also tempered to further reduce stress and more closely control mechanical properties.

How it Works

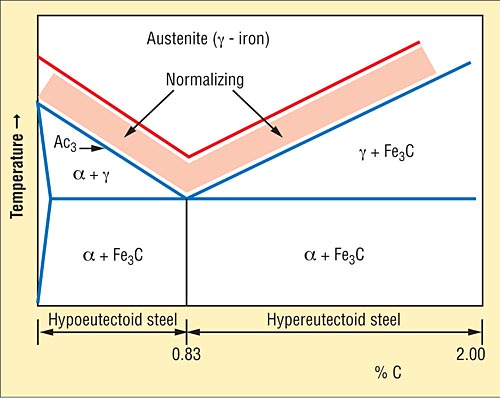

Normalizing is often considered from both a thermal and a microstructural standpoint. In the thermal sense, normalizing is austenitizing followed by a relatively slow cool. In the microstructural sense, the areas of the microstructure that contain about 0.80% carbon are pearlitic, while areas of low carbon are ferritic.

Normalizing vs. Annealing

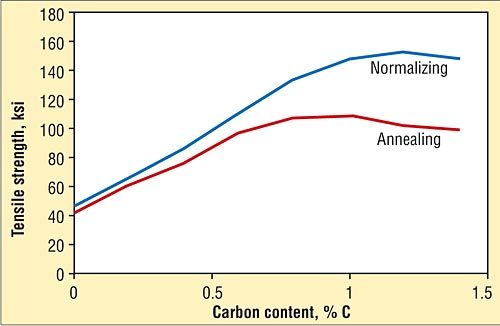

Normalizing differs from annealing in that the metal is heated to a higher temperature and then removed from the furnace for air cooling rather than furnace cooling. For many manufacturing engineers there is often a great deal of confusion as to when to specify normalizing and when to call out annealing. There is a logical reason for this because, in many instances, the procedure for normalizing and that of annealing are one and the same. For example, very-low-carbon steel can be almost fully annealed by heating above the transformation range and cooling in air.

Effect of Normalizing on Physical Properties

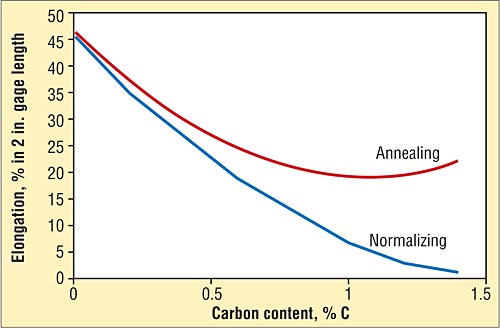

Annealing and normalizing do not present a significant difference on the ductility of low-carbon steels. As the carbon content increases, however, annealing levels off, with respect to a property such as elongation, around 20%. On the other hand, the ductility of the normalized high-carbon steels continues to drop to the 1-2% level.

In Conclusion

Normalizing is a process that improves part quality and plays an important role in controlling dimensional variation in hardening and case hardening. It should be done whenever dimensional stability is important or when manufacturing operations are expected to impart significant amounts of stress into the material. It helps avoid many heat-treating problems.

Read more, here!

If you would like to learn more, please visit Indeeco!